THE DIRECT SPHERE TRANSFER PROCESS

DEK : exclusive licensee

This process recently developed by NOVATEC can be used by Electronic component manufacturers and its role is to attach the spheres to the Ball Grid Array components. It replaces the existing transfer methods and allows multiplication of throughput by 3 to 4.

DIREKT BALL PLACEMENT

DirEKt Ball placement is a development of PROFLOW, which has revolutionised materials transfer for advanced SMT manufacturing. The system features a ball transfer head, developed specifically to enhance processes for grid array packaging. Traversing the stencil, the head actively positions a solder ball at each pad location ; cycle time is fast, consistent and independent of I/O count. Components may be processed in boats, strips, trays or boards.

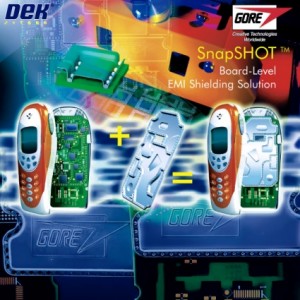

W.L GORE received the EP&P EXCELLENCE AWARD in the category “Hardware, Interconnections & Electromechanical devices” for its snapSHOT™ EMI shield. The snapSHOT™ technology uses the DirEKt ball placement process.DEK Printing Machines received the SMT Vision AWARD in the category “Printing” for its DirEKt Ball Placement ™ process.

Larger substrates, up to 500mm x 400mm, can be processed using DirEKt Ball Placement, compared with traditional ball placement techniques. The ball reservoir is easily interchanged in situ, and the 2-stage hopper design holds up to 50 million solder balls to extend intervals between assists. Product changeover time is under 10 minutes. Handling of solder balls is greatly improved over conventional techniques. DirEKt Ball Attach gently feeds the spheres to the surface of the stencil, preventing knocking an excessive friction inherent in gravity placement methods. Solder balls are transferred to the grid array in perfect condition. The transfer force exerted during placement is sufficient to push the ball down into the flux at each pad location, to enhance the integrity of the assembly during downstream handling and reflow soldering. Flux deposition is also enhanced ; DEK is the world leader in materials transfer technology for the electronics industry, supplying high performance systems for printing solder paste, flux, adhesive, polymers and alloys to the world’s most influential equipment manufacturers. DEK now brings flux deposition in component packaging to new levels of accuracy, repeatability and throughput.