Dosing by printing with VARIDOT

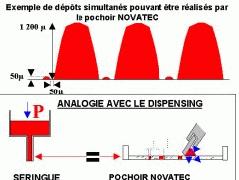

Dosing by printing with VARIDOT a revolutionary and simple printing process, using a one thickness polymer stencil to dose adhesive in multiple dot height in one stroke with a height ratio from 1 to 20.Each stencil aperture works like a syringe needle, the deposit principle follows the same physical rules.The pressure on the syringe piston is equivalent to the transfer force applied on the stencil by the squeegee.

The working principle

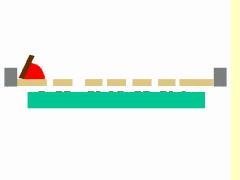

The working principle is a printing process in which the squeegee fills all the stencil apertures simultaneously.The multiple dot height is achieved during the separation between the substrate and the stencil.

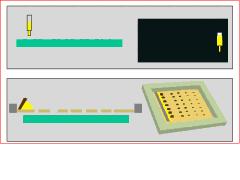

VARIDOT A COLLECTIVE PROCESS

VARIDOT is a collective process with a quasi unlimited throughput. It is an alternative to the traditional syringe dispensing method which only allows it to dose one dot after the other.

It provides :

EXAMPLES

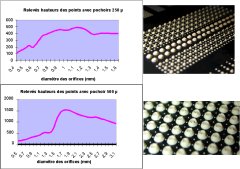

This is an example of deposits achieved with a 250 and a 500 micron thick stencil. Each curve represents the height variation according to the aperture diameter at a given viscosity.

FIELDS OF USE

The deposit of multiple dot height on the pictured printed circuit board illustrates the possible applications in other fields, that is to say any field in which a syringe is used to dose :